Integrated Management System IMS at BSR

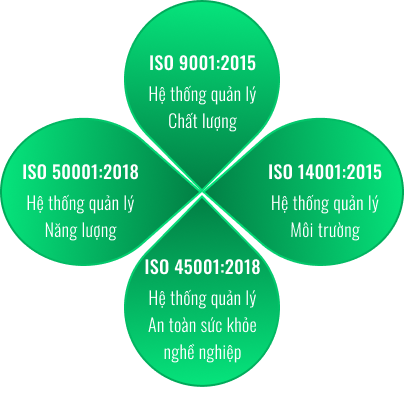

- The Integrated Management System (IMS) of BSR is a system integrated from the Quality Management System according to ISO 9001:2015, Environmental Management System according to ISO 14001:2015, Occupational Health and Safety Management System according to ISO 45001:2018, and Energy Management System according to ISO 50001:2018.

- Application locations (2 locations):

- Head Office: 208 Hung Vuong, Nghia Lo Ward, Quang Ngai Province, Vietnam.

- Dung Quat Refinery (DQR): Van Tuong Commune, Quang Ngai Province.

- Activities and products registered for IMS application: production and trading of refinery products.

- Functional departments applied: all departments under the control and management of the Company's General Director, excluding the DQRE Branch and subsidiaries/affiliated companies.

- Integrated Management System (IMS) Policy:

QUALITY, OCCUPATIONAL HEALTH AND SAFETY, ENVIRONMENTAL, AND ENERGY POLICY OF BSR COMPANY

The Quality, Occupational Health and Safety, Environmental, and Energy (QHSE) Policy of Binh Son Refining and Petrochemical Joint Stock Company (BSR) is: to minimize risks to people, the environment, and assets; to satisfy the growing needs of customers and use energy efficiently and effectively in the production, transportation, and distribution of refining and petrochemical products.

To implement this Policy, the Company commits to establishing and maintaining a Quality, Occupational Health and Safety, Environmental, and Energy Management System to ensure:

1. Full compliance with current legal regulations and obligations;

2. Meeting the QHSE management requirements according to current international standards and continuously improving the system to enhance the Company’s production and business performance;

3. Meeting customer expectations regarding product quality, efficient and effective use of energy and resources, environmental protection, and community well-being;

4. Controlling hazards and risks that may cause occupational accidents, occupational diseases, fires, asset damage, environmental harm, and deterioration of product and service quality;

5. Ensuring that an emergency response plan is established, with personnel readiness and emergency response equipment systems to handle emergencies promptly and effectively;

6. Providing sufficient resources and motivating employees to propose and implement optimal solutions to improve the Company’s quality, safety, environmental, and energy management system;

7. Enhancing training efforts, improving management systems, and necessary documentation to minimize risks in production and business to the lowest possible level;

8. Applying technological techniques, procuring, and using products and services with high energy efficiency.

The leadership and all employees of the Company strive to achieve this Policy.

Certificates

Environmental Work