BSR Aims for a Circular Economy Model: Optimizing Production and Sustainable Development

Binh Son Refining and Petrochemical Joint Stock Company (BSR) recently organized a seminar on "Developing a Circular Economy at BSR". The event was attended by Mr. Mai Tuan Dat, BSR's Deputy General Director, Refinery Management Board, representatives from specialized departments directly related to the refinery, along with dedicated employees and personnel.

Circular Economy – A Sustainable Growth Trend

The traditional linear economic model (also known as the straight economy) follows a "take - make - consume - dispose" approach, leading to significant resource waste.

Meanwhile, the circular economy (CE) model represents a key trend in the development of a green economy, aiming to reduce resource extraction, minimize waste generation, and mitigate negative environmental impacts, ultimately promoting sustainable development.

The CE is a new economic model based on the fundamental principle that “everything is an input for something else.” In other words, it transforms waste outputs from one industry into valuable inputs for another or recirculates them within a single enterprise.

The circular economy (CE) is built on the fundamental 3R principles under ISO 14001: Reduce, Reuse, and Recycle. Reduce involves using fewer resources and minimizing waste generation. Reuse extends the lifecycle of products and materials by utilizing them multiple times. Recycle transforms waste into new raw materials for manufacturing other products. This approach not only optimizes resource efficiency but also mitigates environmental impact.

In Vietnam, the government has actively promoted the CE model through the project "Developing a Circular Economy in Vietnam," approved by the Prime Minister under Decision No. 687/QĐ-TTg on June 7, 2022. The initiative aims to accelerate the adoption of circular economic practices and establish a green lifestyle, with the ultimate goal of achieving net-zero greenhouse gas emissions by 2050.

For businesses, implementing the CE model brings significant advantages. Environmental protection is enhanced through reduced waste, minimized pollution, and the conservation of natural resources. Cost savings are achieved by lowering production and waste treatment expenses. Additionally, the CE model unlocks economic opportunities by fostering innovation, creating new industries, and strengthening business competitiveness.

By embracing the circular economy, businesses can increase their value, reduce resource exploitation, lower waste management costs, and contribute to a cleaner environment. This sustainable approach not only supports long-term economic growth but also aligns with global trends in environmental responsibility.

Circular Economy Development Strategy at BSR

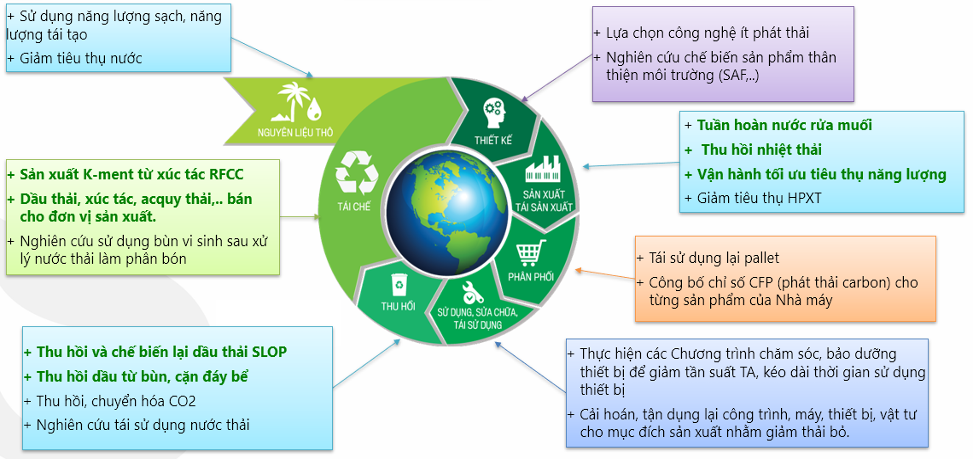

At BSR, various initiatives are being implemented to reduce resource extraction, minimize energy consumption, and limit environmental emissions. Key circular economy solutions include: recycling wash water, recovering waste heat, optimizing energy consumption, reducing chemical usage, minimizing water consumption, and recovering oil from sludge and tank bottoms. Additionally, BSR has taken steps to reduce FO oil combustion and has collaborated on the production of K-ment, an eco-friendly product derived from used RFCC catalysts. These efforts align with the company’s commitment to sustainability and the transition towards a greener, more efficient refinery operation.

At the seminar, participants contributed various proposals and ideas to develop a comprehensive and effective circular economy model at BSR. Key initiatives include a pre-feasibility study (Pre-FS) for Sustainable Aviation Fuel (SAF) production at Dung Quat Refinery to support the green energy transition and the development of a high-tech pilot system for microalgae biomass production for advanced biofuels. BSR also aims to install wind power plants and rooftop solar projects to supply renewable energy, while transitioning from FO combustion to LNG as a cleaner fuel alternative. Additionally, a feasibility study on producing carbon nano-materials from CO₂ in flue gas is being explored for battery and energy storage applications. Other initiatives include a pre-feasibility study on wastewater reuse to reduce resource consumption and environmental impact, as well as the recovery of silica or alumina from spent RFCC catalysts for use in solid-state battery materials. These efforts demonstrate BSR’s commitment to enhancing resource efficiency, reducing environmental impact, and driving sustainable innovation.

The seminar proposed a circular economy model at BSR.

In his concluding remarks at the seminar, Mr. Mai Tuan Dat, Deputy General Director of BSR, emphasized that developing a circular economy is an inevitable trend to optimize resources and protect the environment. He reaffirmed that BSR's specialized departments will continue to promote circular economy solutions, not only to enhance production efficiency but also to demonstrate corporate responsibility toward the community and the environment. BSR is committed to researching and adopting advanced technologies while collaborating with partners to implement circular economy practices in the most effective way.

The adoption of a circular economy model enables BSR to reduce environmental impact, drive sustainable growth, and optimize production efficiency, ultimately delivering significant economic value for the company.

Trang Nhung

Keywords