General introduction

Introduction of construction works of Dung Quat Oil Refinery - Vietnam's first oil refinery

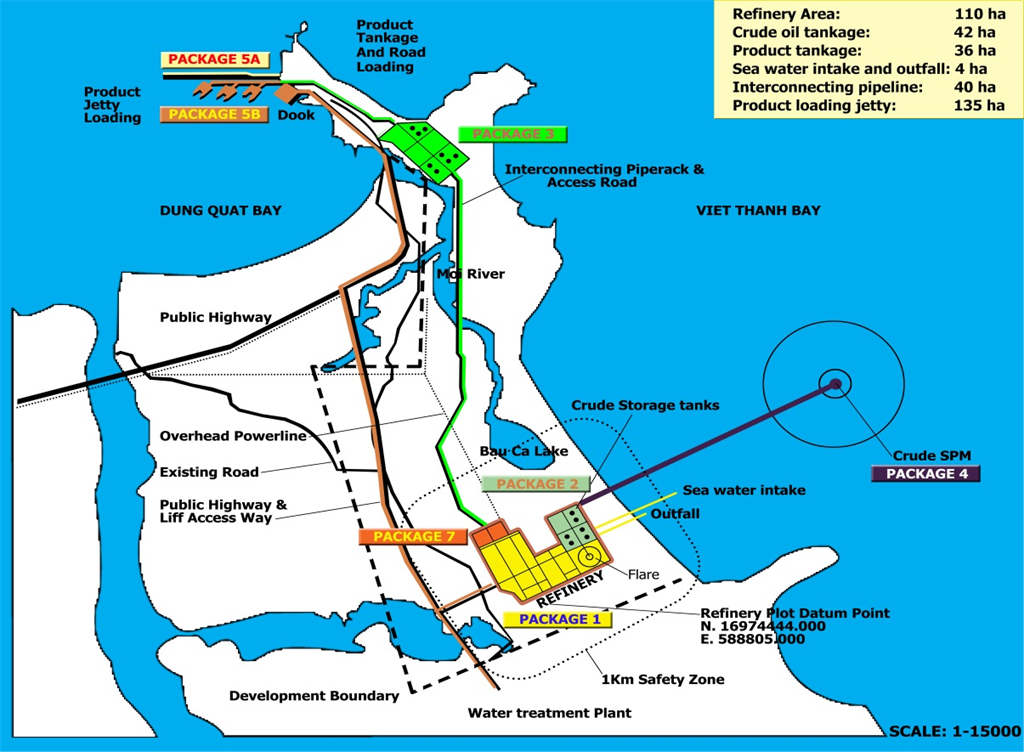

1.Location and Area of use

Location:

The factory was built in Dung Quat Economic Zone, located in Binh Thuan and Binh Tri communes, Binh Son district, Quang Ngai province.

Area of use:

About 956 hectares (including 140 hectares for future expansion) including 485 hectares of land and 471 hectares of sea surface, of which (currently): 110 hectares of the main factory; Crude oil storage area 42 ha; Product storage area 43.83 ha; Crude oil pipeline area, sea water supply and discharge 17 ha; Product pipeline route 77.46 ha; Product export port 135 ha and berthless oil import buoy system, undersea pipeline and ship turning area 336 ha.

2. Processing capacity and raw materials

Processing capacity: 6.5 million tons of crude oil/year, equivalent to 148,000 barrels/day. After completing the expansion upgrade: 8.5 million tons of crude oil/year, equivalent to 192,000 barrels/day.

Material

-

Stage 1: Processing 100% of Bach Ho - Vietnam crude oil (or equivalent crude oil).

-

Stage 2: Processing sour oil.

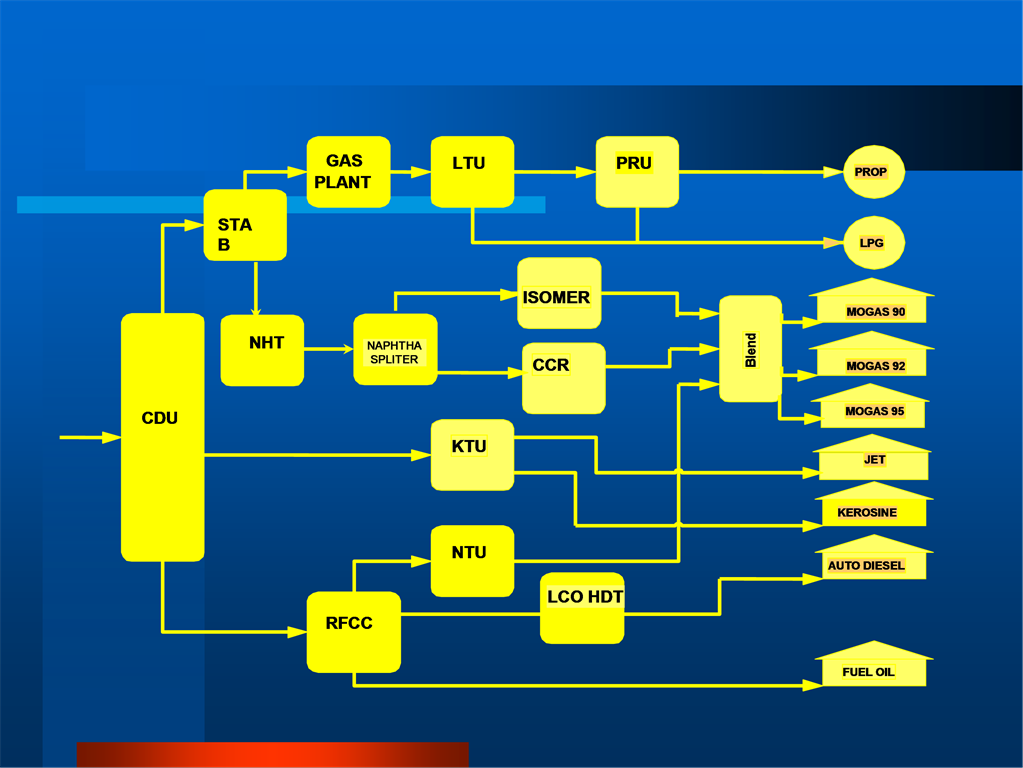

3. Technology configuration

4. Operation Process of Oil Refinery

-

Crude oil is imported into the refinery for processing through a single-point mooring buoy system (SPM) capable of receiving ships with a tonnage of 80,000 to 150,000 tons (After upgrading and expanding 300,000 tons) and the oil pipeline from the float to the crude oil storage area is about 4.2 km long.

-

Crude oil is pumped into the crude oil storage area including 08 tanks with equal capacity, each tank is 65,000m3. Then crude oil is pumped into the atmospheric distillation tower with a capacity of 140,000 barrels a day to separate into segments such as: Gas, Naptha, Kerosen, Heavy and light Gas oil and atmospheric residue.

-

Gas is brought to the Gas processing workshop and Propylene is recovered to produce liquefied gas and Propylene is sent to the Polypropylene plant to process plastic beads.

-

Naptha is brought to technology workshops to improve the octane number of gasoline blends.

-

Kerosen is taken to the kerosen processing plant to produce Jet A1 jet fuel and kerosene.

-

Heavy and light gas oil is sent to the processing segments to produce diesel oil.

-

Atmospheric residues are taken to the treatment workshop to produce products: gasoline, diesel, fuel oil...

-

All technology and auxiliary workshops of the Factory are operated at the Central Control House through a modern DCS distributed control system with control, monitoring, recording, storage and display functions. Plant operation data.

-

To serve the operating technology workshops, the refinery has 10 auxiliary workshops such as power plants, workshops supplying compressed air and control gas, chemicals, cooling water, fire-fighting water and domestic water. , fuel gas, fuel oil, wastewater treatment workshop...

-

Products from the technology area are brought to the intermediate storage area, where the products are checked for quality and mixed at a reasonable rate before being sent to the product storage area by long pipes. about 7 km.

-

The products of the factory are stored in 22 tanks of finished products and sold by road and by sea to export all products of the factory.

-

The port for exporting products by sea is located in Dung Quat Bay, about 3 km from the Product Storage Area. The port of exporting products by sea exports products through 6 berths for ships with a tonnage of 1,000 to 30,000 tons.

-

In order to prevent waves, protect the product export port of the refinery and other works in Dung Quat Bay, a breakwater was built with a total length of nearly 1,600m, the dike surface is 11m wide, and the height of the dyke is compared to the surface. sea water from 10 to 11m.

5. Product structure

| Products | Thousand tons/year |

|---|---|

| Propylene | 136 - 150 |

| Liquified Petroleum Gas (LPG) | 400 - 420 |

| RON 92 | 1.400 – 1.800 |

| RON A95 | 600 - 700 |

| Jet A1. kerosene/flying fuel | 80 - 400 |

| Automotive Diesel Oil | 2.900 – 3.200 |

| Fuel Oil (FO) | 60 - 100 |

| Polypropylene | 135 - 150 |

| Sulfur | 1,5 - 2 |

6. Total investment

-

According to Decision 514/QD-TTg dated 10/7/1997 (self-investment period from 1997 to 1999): Total investment is 1.5 billion USD;

-

According to Decision 560/CP-DK dated June 21, 2001 of the Government (JV phase with Russia): The total investment for the project is USD 1,297 billion excluding financial fees;

-

According to Decision 546/QD-TTg dated June 17, 2005 (Stage to return to self-investment): US$2,501 billion; According to Decision 546/QD-TTg dated June 17, 2005 (Stage back to form). self-investment mode): USD 2,501 billion;

-

According to Decision No. 1291/QD-TTg dated August 17, 2009 (after completing the construction and testing of the factory): Approving the total investment of 3.053 billion USD.

Introduction of project items