Improving Laboratory Analysis Methods: BSR Engineers Generate Over VND 1 Billion in Annual Savings

Each year, the Laboratory of Binh Son Refining and Petrochemical Joint Stock Company (BSR) conducts hundreds of tests to control the quality of catalysts used in the “heart” of the Dung Quat Refinery - the RFCC unit. From an anomaly detected in arsenic (As) analysis results, BSR engineers independently researched and improved the testing method, corrected analytical errors, mastered the process, and helped the Refinery save more than VND 1 billion annually. This story goes beyond a technical initiative, reflecting the spirit of innovation, responsibility, and persistent creativity of BSR’s scientific workforce.

From the “heart” of the Refinery to the catalyst challenge

In the operating process of the Dung Quat Refinery, the RFCC (Residue Fluid Catalytic Cracking) unit is regarded as the “heart” of the entire system. This is where heavy residues from crude distillation (CDU) are converted into high-value light products such as gasoline, LPG, propylene, diesel, and fuel oil.

The RFCC complex comprises four main sections: the reactor, catalyst regeneration system, product fractionation, and gas/by-product treatment. With a design capacity of approximately 69,700 barrels per day, the RFCC unit is currently capable of operating at over 110% of capacity under optimal conditions - clear evidence of the technical expertise, operational capability, and continuous improvement efforts of BSR engineers.

At the core of RFCC processing is the catalyst, which determines both efficiency and product quality. The catalyst used is a fine powdered zeolite with an average particle size of about 70 microns, operating in a pseudo-fluidized bed to facilitate the cracking of long-chain hydrocarbons in heavy feedstock. The system typically contains 600–650 tonnes of equilibrium catalyst, with a daily addition of 8-13 tonnes of fresh catalyst.

Correspondingly, the volume of spent catalyst discharged is nearly equal to the amount of fresh catalyst added, averaging around 10 tonnes per day. This spent catalyst is collected at designated locations such as Hopper D-1506 and the Fine Silo, then classified and treated in accordance with national regulation QCVN 07:2009/BTNMT on hazardous waste thresholds. Since the Refinery began operation, RFCC spent catalyst samples have been sent to external testing agencies for analysis, with results consistently meeting requirements—below hazardous waste thresholds.

However, on March 21, 2023, the testing agency reported an arsenic concentration of 8.05 mg/L in the catalyst batch dated February 24, 2023, exceeding the 2 mg/L threshold for non-hazardous waste. If confirmed, this RFCC catalyst batch would have to be classified and treated as hazardous waste, resulting in a sharp cost increase - from VND 736,000 per tonne to VND 4.6 million per tonne.

Faced with this “abnormal” result and assigned the task, engineers from the Laboratory re-analyzed all feedstocks, chemicals, and additives used in the RFCC unit to trace potential sources of arsenic accumulation. The reassessment showed that none of the sources contained arsenic at levels high enough to accumulate beyond the threshold in the catalyst. This led to an initial conclusion that the analytical method used by the service provider might have been subject to interference, causing a positive bias in the test results.

When BSR engineers diagnose the issue and find their own solution

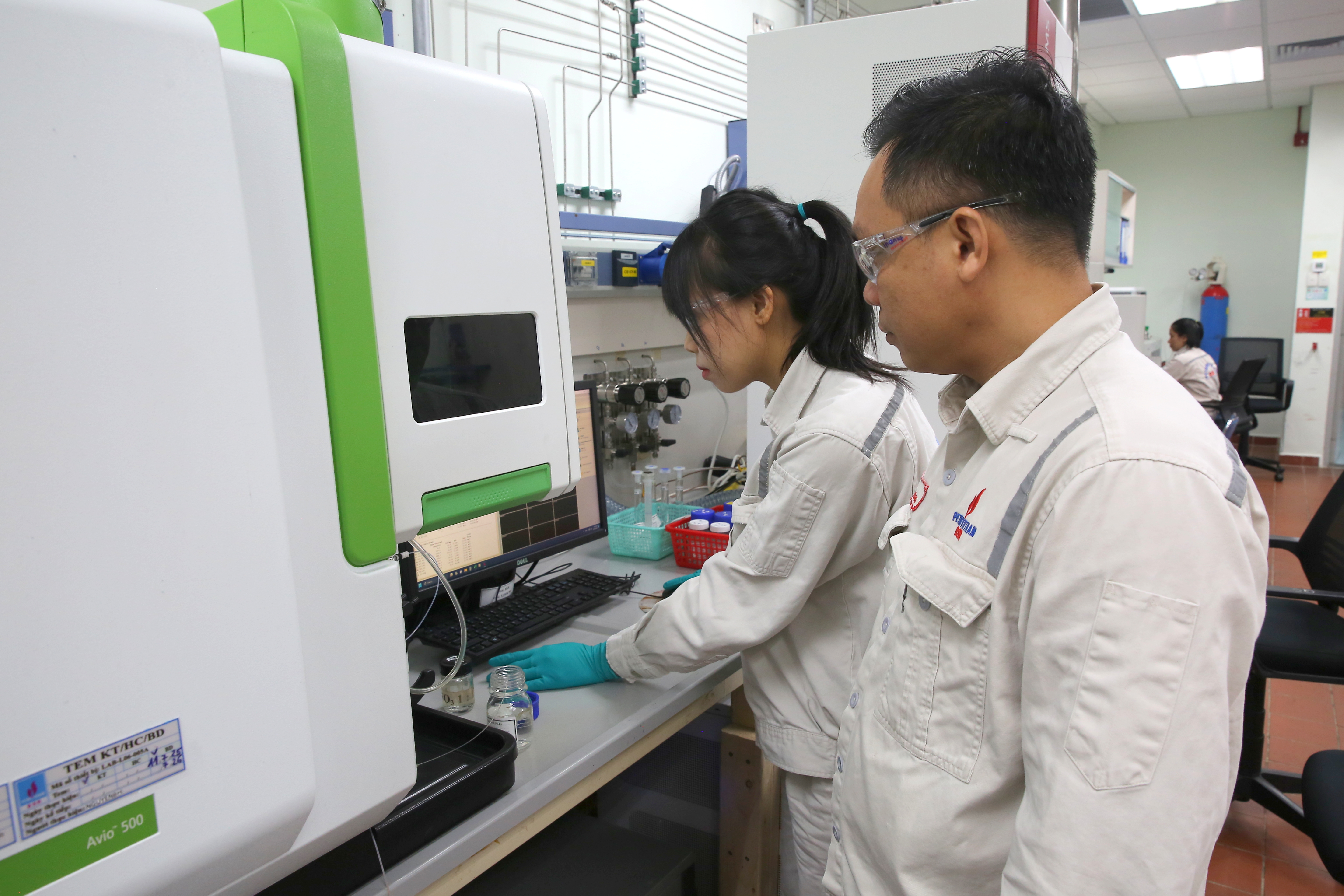

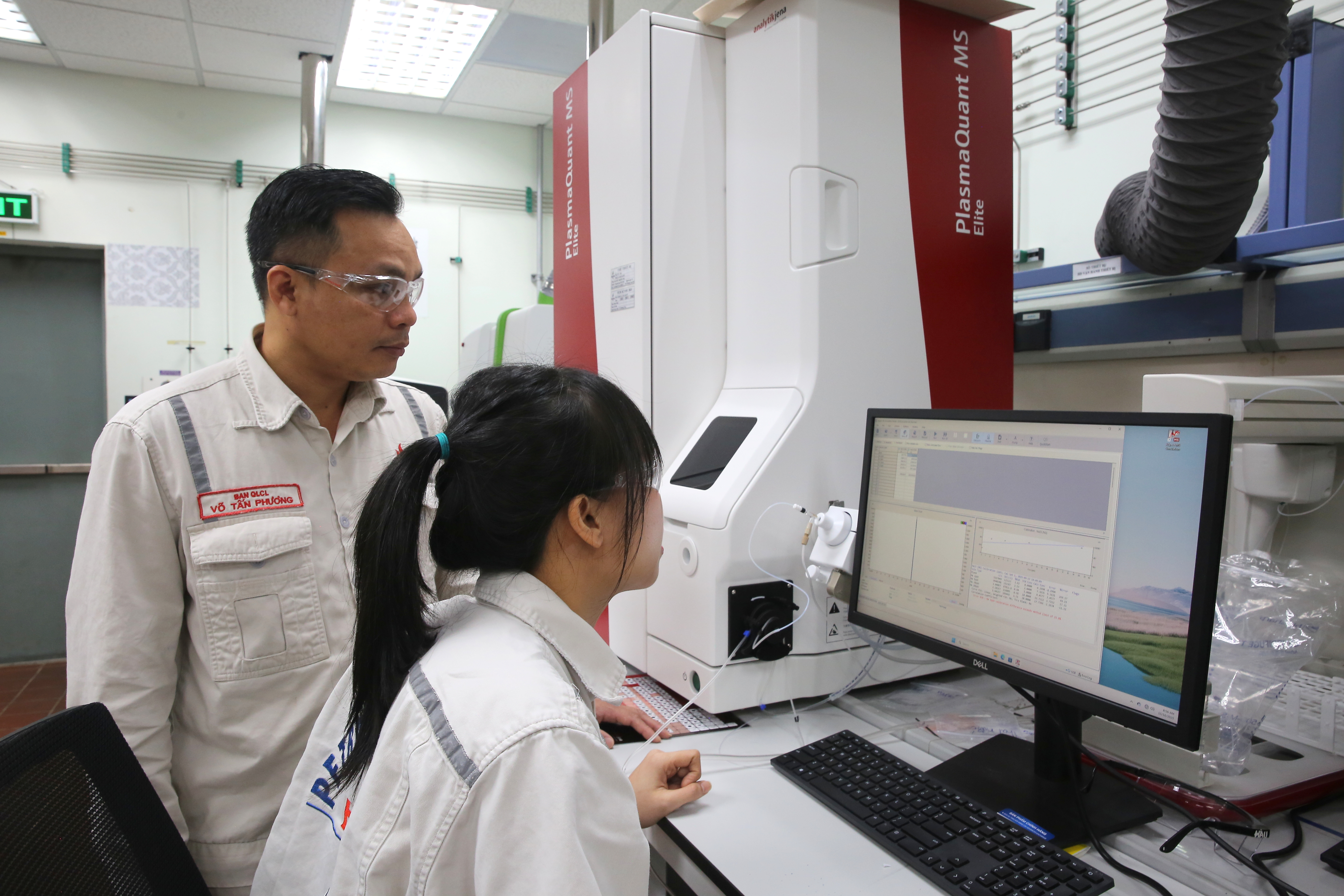

In response, the BSR Laboratory engineering team, led by Engineer Vo Tan Phuong, began researching and developing an in-house analytical method to fully replace outsourced testing. This task required not only advanced analytical chemistry expertise but also a deep understanding of RFCC process technology.

Under the original design, the BSR Laboratory was not equipped to analyze extractable metals such as arsenic and antimony in catalysts. However, given the urgent need, the team proactively leveraged existing equipment - particularly ICP-OES and a rotary evaporator - to re-establish the entire metal extraction process in accordance with EPA 200.7 and 1311 standards, adapted to local conditions.

This creative solution completely replaced costly specialized equipment with an available rotary evaporator, enabling effective extraction of metals from catalysts into the aqueous phase. Notably, the research team identified interference from the rare earth element lanthanum (La), naturally present in zeolite catalysts, as the primary cause of distorted arsenic results. Through extensive experimentation, the team developed measures to eliminate this interference, ensuring high analytical accuracy on the ICP-OES at wavelengths of 193 nm and 197 nm.

This “home-grown” solution not only significantly improved analytical accuracy but also fully met the technical requirements of ISO 17025. The results were impressive: when applying the new method, re-tested RFCC catalyst samples all fell within safe limits, below hazardous waste thresholds. Notably, the team collaborated to transfer the solution to the external testing agency for re-analysis of the aforementioned catalyst batch.

After adopting BSR’s recommendations, the testing agency reissued the results for the February 24, 2023 batch, confirming that arsenic levels were below regulatory limits - validating the accuracy and practical value of the initiative.

The initiative titled “Improving the analytical method for arsenic and antimony (EPA 200.7 & 1311) in RFCC catalysts to enhance test accuracy” won First Prize at the 14th Quang Ngai Provincial Technical Innovation Contest (2024–2025). From a technical and environmental perspective, the new method enables the BSR Laboratory to fully control catalyst quality, calculate and adjust Ni passivator dosage, and accurately classify spent catalysts in compliance with QCVN 07:2009/BTNMT—ensuring regulatory compliance while optimizing waste treatment costs.

From an economic standpoint, the benefits are even clearer. Previously, the BSR Laboratory sent approximately 208 spent catalyst samples annually to external labs, at an average cost of VND 5.28 million per sample. By conducting analyses in-house, the cost has been reduced to just VND 313,033 per sample. As a result, BSR saves approximately VND 1.033 billion each year - excluding additional indirect benefits from faster, more proactive quality control and timely process adjustments.

Mr. Pham Cong Nguyen, General Manager of BSR’s Safety and Quality Division, commented:

“Looking back on the entire journey, this initiative is not merely a story about a single test or a minor technical step. Behind it lies a spirit of creativity, proactivity, and scientific rigor - values that are deeply embedded in BSR’s culture of innovation.

From detecting abnormal signs, diagnosing the issue, analyzing and identifying root causes, to developing a complete alternative method, BSR engineers have demonstrated their ability to master technology and their boundless creativity. They not only resolved a specific technical problem but also contributed to cost reduction, enhanced production sustainability, and affirmed the mettle of ‘BSR people’ - speaking less, thinking more, doing more, acting fast, and delivering high efficiency.”

With intellect and dedication, BSR Laboratory engineers have turned seemingly modest laboratory tasks into a solution delivering more than VND 1 billion in annual benefits. This story once again affirms that at the Dung Quat Refinery, every initiative and improvement - whether in the laboratory or the production process - is a small brick that helps build great value for the enterprise and for Vietnam’s energy and petrochemical industry.

BSR

Keywords